Quality Inspection for Air Drier - Injection pump – Quanlee

Quality Inspection for Air Drier - Injection pump – Quanlee Detail:

| Products Name | Installation Position | Effect |

| Output Oil Valve | High Pressure Oil Pump | Discharge Of Oil |

| Flexible Connection Strap | Rear Coupling | 、Buffering And Power Transfer |

| Alternator | Mounted On The Upper Right Front Of The Engine | Battery Charging |

| Engine Four Supporting | The Center Of Engine | The Power Core Component Of An Engine |

| Compressed Air Cylinder | Install On High Pressure Oil Pump | Accelerate And Extinguish |

| Engine Repair Kit | The Engine | Engine Repair Kit |

| Euro ⅱEngine New Model | Underpan | Provide Power Source For The Whole Machine |

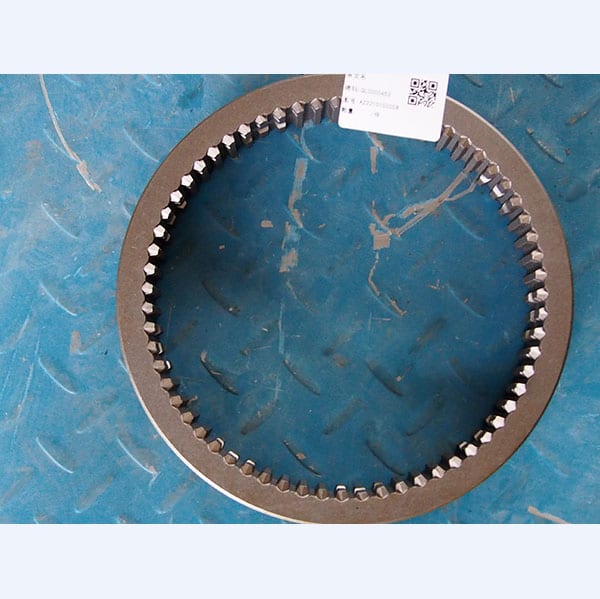

| Flywheel | The Crankshaft Backend | The Output Of The Engine’s Dynamic Inertia |

| Flywheel Housing | The Back End Of The Engine | Connect The Housing Of The Power Output End Of The Engine |

| Fan | Water Pump Front End | Cooling Tank And Engine |

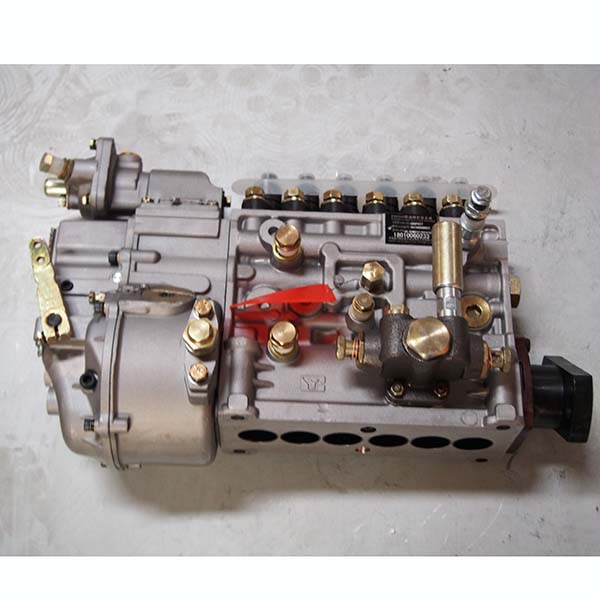

| Injection Pump | Right Side Of The Engine | Each Cylinder Of Fuel Injection, Increase The Diesel Pressure, Distribution Of High Pressure |

| Injection Pump Repair Kit | High Pressure Oil Pump | Repair High Pressure Oil Pump |

| Rear Exhaust Manifold | At The Right Of Engine | Exhaust Gases |

| Piston | ,Above The Connecting Rod, And Inside The Cylinder Liner | Compression The Air |

| Oil Pump | ,,The Front Of The Crankcase, The Underside Of The Chamber, And The Inside Of The Sump | Inhalation Of Engine Oil |

| Intake Valve Rock Arm | Inside The Valve Chamber Cover Of The Cylinder Cover | Push The Upward Or Downward Thrust Of An Inlet Valve |

| Connecting Rod | Above The Crankshaft Connecting Rod Shaft | Upward And Downward Motion Of a Piston |

| Connecting Rod Bolt | Head Of Connecting Rod | Tighten Connecting Rod Body And Connecting Rod Cover |

| Connecting Rod Bearing | Inside The Connecting Rod Socket | Wear Resistance Between Crankshaft And Connecting Rod |

| Coupling Flange Fitting | On The Engine | Connect The Air Compressor To The Fuel Injection Pump |

| Air Exhaust Pipe Gasket | Between Exhaust Pipes | 、Seal And Prevent Air Leakage |

| Exhaust Valve Rock Arm | Inside The Valve Chamber Cover Of The Cylinder Cover | a Push To Open The Exhaust Valve Up And Down |

| Unidirectional Valve | High Pressure Oil Pump | Control The One-Way Flow Of Oil |

| Injection Nozzle | Fuel Injector | Spray The Liquid Oil |

| Belt | Between The Water Pump And The Crankshaft Pulley | Turn The Pump |

| Starter | Installed In The Flywheel Housing With Flywheel Gear Ring Joint | Starting Engine |

| Euro Ii Cylinder Head Gasket | Between Cylinder Head And Cylinder Body | Seal Between Cylinder Head And Cylinder Body |

| Cylinder Head | The Upper Plane Of The Cylinder Block | a Combustion Chamber Is Formed In Conjunction With The Cylinder Liner |

| Cylinder Head Cover | Top End Of Cylinder Head | Seal, Dust Proof |

| Cylinder Liner | Inside The Cylinder Bore | ,,The Piston Moves Up And Down, To Prevent Pulling Out The Bearing Hole Of The Cylinder Block, Which Is Combined With The Piston To Form The Combustion Chamber |

| Valve Rock Arm Seat | The Top Of The Cylinder Head | Valve Rocker Arm Support Point |

| Front Exhaust Manifold | Engine Right | Exhaust Gases |

| Crankshaft | The Center Of The Cylinder Body And Crankcase | Wear Resistance Between Main Shaft Diameter And Cylinder Body |

| Hand Oil Pump | Above The Fuel Pump | Fuel Input |

| Double Cylinder Air Compressor Repair Kit | Air Compressor Assembly | ()Repair Air Compressor (Including All Seals Of Air Compressor) |

| Double Cylinder Air Compressor | ,The Front End Of The Engine, Above The Timing Gear Compartment | ,Produce Pneumatic Brake, Brake Gas |

| Water Pump | Front End Of Timing Gear Chamber | Engine Cooling Water Circulation |

| Compressor Bracket | The Upper Front Of Engine | Installation Compressor |

| Turbocharger | ,The Rear Part Of The Engine And The Upper Part Of The Flywheel Housing | Increase The Intake And Exhaust Of The Engine |

| Turbocharger Oil Intake Pipe | Between The Supercharger And The Cylinder Body | The Transfer Of Excess Oil From The Supercharger To The Oil Sump |

| Turbocharger Kit | The Supercharger | Repair The Supercharger |

| Stop Washer | On The Crankshaft | Fixed Function |

| Starter | Install In The Flywheel Housing With Flywheel Gear Ring Joint | Drive The Engine Running |

| Plunger | Install On The Right Side Of The Cylinder Block | Seal Water |

| Automatic Pulley | Timing Gear Room | Adjust The Belt Tightness |

Product detail pictures:

Related Product Guide:

2019 BMW M850i xDrive Convertible Review: GT To A Tee | Heavy Truck Power Steering Pump

Tata Nexon gets aesthetic, interior upgrades- Business News | Planet Carrier Assy.

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for Quality Inspection for Air Drier - Injection pump – Quanlee , The product will supply to all over the world, such as: St. Petersburg , Greenland , Chile , Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

Write your message here and send it to us